The Future of Oil and Gas

How 3D Laser Scanning is Transforming Industry Norms

The oil and gas sector is a cornerstone of the global energy infrastructure. As pressures from environmental concerns, operational efficiency, geopolitical events, and safety protocols mount, there is an undeniable need for innovation. 3D laser scanning, an emerging technology, is proving to be that innovation, profoundly altering how the industry operates. In this article, we’ll delve deep into how 3D laser scanning is transforming the very tenets of project execution, safety assurance, and profitability.

Traditional Limitations

For years, the oil and gas sector has been entrenched in a set of practices that, though functional, have revealed limitations as the industry matures. The use of manual labor for field data collection and 2D CAD drawings for planning has led to multiple challenges. Human errors, approximation, and the extended timeframes needed for data collection have hindered productivity and added risks. Acknowledging the challenges of these methods does not detract from the many skilled and qualified workers who have laid the foundation of our global energy infrastructure for decades. Instead, it serves as inspiration to honor past efforts while seeking ways to elevate our workforce with better tools to move the industry forward.

The Push for Modernization

Tighter regulations and increasing scrutiny from both governmental bodies and the public are demanding more—more accuracy, more efficiency, and more accountability. Consequently, the traditional methods are no longer sufficient; there’s an increasing push for digital transformation to meet these challenges head-on. Where many organizations struggle is the practical application of digital technology that has an immediate positive impact on operations and business performance.

Basic Mechanics

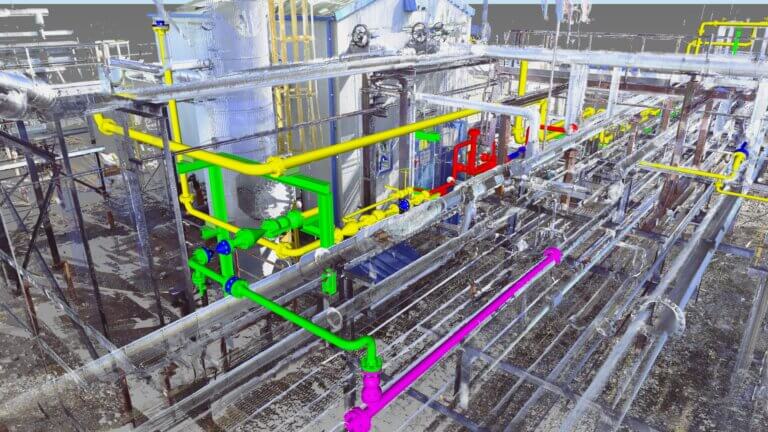

3D laser scanning may seem like something out of a science fiction novel but is profoundly rooted in practical applications. Using lasers to send and receive signals that measure distances between surfaces, this technology gathers data points in ‘clouds.’ Think of each point as a pixel in three-dimensional space. The same way that a collection of pixels on a television can form a realistic two-dimensional image, a point cloud is a collection of points that form an accurate three-dimensional representation of an object. These point clouds are dimensionally accurate, can be registered geospatially, and serve as the raw material to develop highly accurate 3D models for engineering, design, analysis, and planning.

Broad Applications

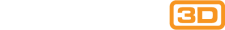

The transition from physical to digital using 3D laser scanning allows engineers, designers, and project managers to visualize layouts, identify potential flaws, and rectify them in the design phase long before actual construction or modification begins. The applications span across initial explorations, construction, and even maintenance in the later stages of a facility’s life. If the accuracy tolerance of the point cloud is high enough, fabrication drawings and as-built packages can be created from the data, exponentially saving on field time and re-work issues that can occur in traditional measurement methods.

The Impact of 3D Laser Scanning

The accuracy level attainable through 3D laser scanning is unprecedented in the industry. Traditional measuring tools and human judgment inherently have a margin of error. However, 3D laser scanning reduces these errors to a negligible minimum. For example, in complex pipeline configurations, the ability to capture every curve, joint, and intersection translates into a more efficient construction process with fewer adjustments required along the way.

Time is another crucial resource saved. The data collection process, which could traditionally take several weeks or even months depending on the project scale, can be completed much more quickly. This swift action not only speeds up project initiation but also significantly reduces downtime during renovations or upgrades, allowing production to resume more promptly.

In a sector where safety is not just a priority but a core value, the potential for 3D laser scanning to enhance safety measures is priceless. The accuracy of 3D models ensures that safety protocols are based on actual site conditions rather than approximations. These models can be used for safety drills, planning emergency exits, and assessing potential hazard zones, thereby minimizing risks.

The transition from physical to digital using 3D laser scanning allows engineers, designers, and project managers to visualize layouts, identify potential flaws, and rectify them in the design phase long before actual construction or modification begins.

Our journey into integrating 3D laser scanning into the oil and gas workflow wasn’t an overnight decision; it was a strategic pivot aimed at harnessing technology to meet contemporary challenges. Through our investments in state-of-the-art technologies like LIDAR, 3D modeling, and point clouds, transformed the traditional project execution approach into a seamless, efficient, and remarkably accurate process. Using the Integrated Project Delivery (IPD) model, projects are successfully completed with technical precision that would simply not be possible without use of technology.

Acceptance of 3D laser scanning isn’t limited to future-focused companies; it’s becoming an industry standard. Surveys and reports indicate that companies implementing this technology have achieved up to a 25% reduction in both project costs and time-to-completion. These figures aren’t merely statistical points but a testament to the operational efficiencies the technology introduces.

As we look toward the future, advancements in AI and machine learning promise even more potent applications for 3D laser scanning. Coupled with the IoT, there’s potential for real-time, dynamic modeling and predictive maintenance—capabilities that would further revolutionize the industry.

Integrating a new technology into existing workflows is a critical undertaking. Companies need to evaluate scalability, ensuring the technology can flexibly adapt to both small and expansive projects. A thorough cost-benefit analysis, projecting both immediate and long-term ROI, is essential. Finally, the human element can’t be overlooked. Proper training to upskill the team ensures that the technology is effectively utilized.

3D laser scanning is not a passing trend but a disruptive technology setting new industry standards. Its benefits of enhanced accuracy, cost-saving, time-efficiency, and improved safety protocols offer oil and gas companies a robust framework to meet and exceed current challenges.